Safety

Safety is at the Forefront of Everything We Do

At Haverfield, safety is our number one priority. To maintain a safe environment for employees and customers, Haverfield utilizes a comprehensive safety program.

Daily Tailboards

Stop Work Policy

Our stop work policy gives authority to any person on the crew to stop a project when potentially unsafe working conditions arise. We value each employee’s contribution to the team and feel each one of our crew has the safety training and integrity to make these decisions if needed.

Safety Audits

Monthly Safety Committees

Safety Committee Meetings provide a feedback and learning loop for ongoing improvements and a continuous commitment to safety. These meetings review items in the company hazard log for areas of strength and improvement and to ensure that we are constantly evaluating our safety needs.

Bi-Weekly Safety Calls

Every other week, Haverfield holds an “All Staff” Safety conference call where every employee is required to participate. This call gives the entire Haverfield Team a forum to openly discuss ongoing safety policies & procedures, as well as the presentation of formal safety lessons.

Safety Management System

Training

Haverfield focuses on a comprehensive training program that ensures all employees have the knowledge to remain safe at all times.

Haverfield Training

Haverfield has a long history of being an industry leaders in both aerial linework techniques and safety. Part of maintaining a safe working environment has been developing comprehensive training programs to support our history of excellence and dedication to quality.

We are proud to partner with the Northwest Lineman College and our parent company, Quanta Services, to deliver state of the art training opportunities to our employees. The various training curricula not only address what we have learned from prior experience, they also act as proactive forums to establish industry best practices for the future.

The Capacity Model

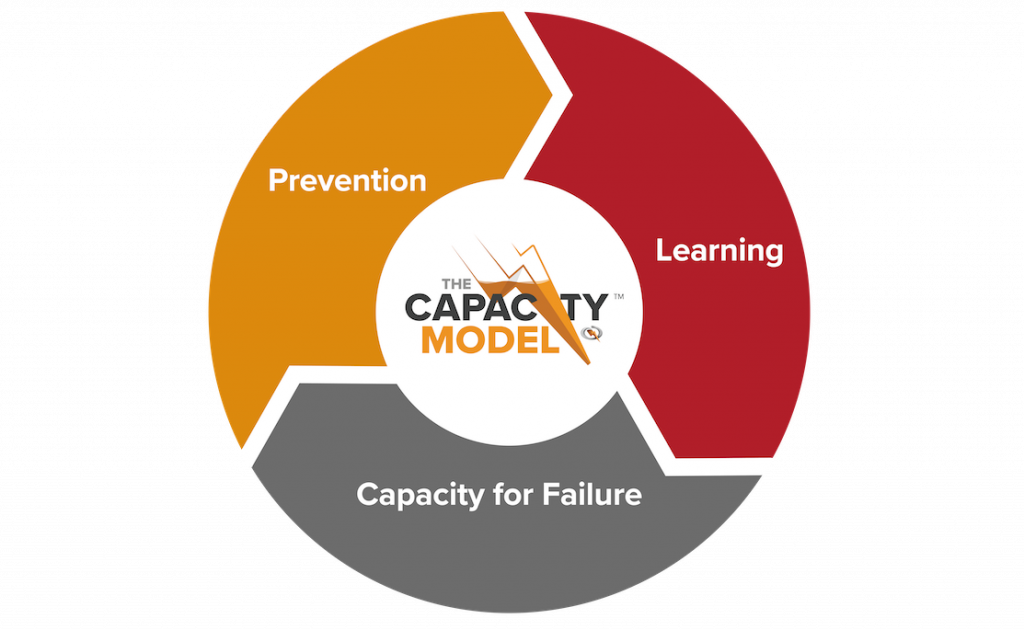

As part of the Quanta family we have adopted many of their core operating principles. One of those is the Capacity Model.

The Capacity to Fail Safely

“We are in the people business and we know that people are fallible. We always choose prevention, but we realize that mistakes will happen. The question becomes do we have the capacity to absorb failure without causing harm. To be ready, we will plan and execute work assuming that failure could happen at any moment. We will learn from each job, each mistake and success – to continue getting better in every aspect. Safety is not the complete absence of injuries – it is the presence of capacity. Safety is not just a policy – safety is the core of who we are and always at the forefront of our focus.” – Quanta Services